MIM

MIM combines the advantages of plastic injection and powder metallurgy.

MIM

MIM combines the advantages of plastic injection and powder metallurgy.

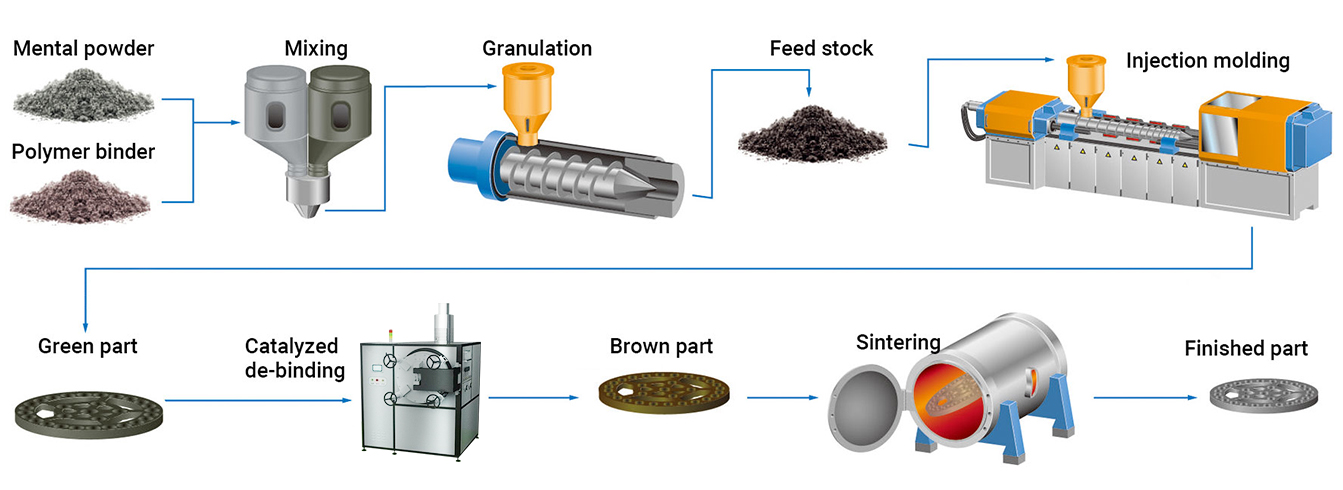

Metal injection molding (MIM) is a typical interdisciplinary product that integrates two completely different processing processes (plastic injection molding and powder metallurgy).This allows designers to break free from traditional constraints and obtain low-priced, profile-shaped stainless steel, nickel, iron, copper, titanium and other metal parts in a plastic-molded fashion, giving them greater design freedom than many other production processes.

To live up our customers’ high demands, UNION operates a state-of-the-art quality and environmental protection program.

This includes: UINION companies have ISO 9001、ISO 014001、IATF 16949 、SO 45001 certification.

In terms of testing equipment, we have the following equipment

Manager

and above

Average seniority 12 years

Assistant

Manager

Average seniority 10 years

Section

Manager

Average seniority 7 years

Team

Leader

Average seniority 5 years