According to the manufacturer of shock absorbing spring, special attention should be paid to decarburization and surface quality in rolling process of spring steel. When the steel surface is seriously decarburized, the fatigue limit of steel will be significantly reduced. For high silicon spring steels such as 70Si3MnA, graphitization should be avoided. Therefore, the stop-rolling temperature should not be too low (≥850℃) during hot processing, and the residence time should not be too long in the temperature range (650 ~ 800℃) where graphitization is easy to form.

After the spring is made, shot peening treatment can make the spring surface produce residual compressive stress, to offset part of the working stress on the surface, inhibit the formation of surface cracks, which can significantly improve the fatigue limit of the spring.

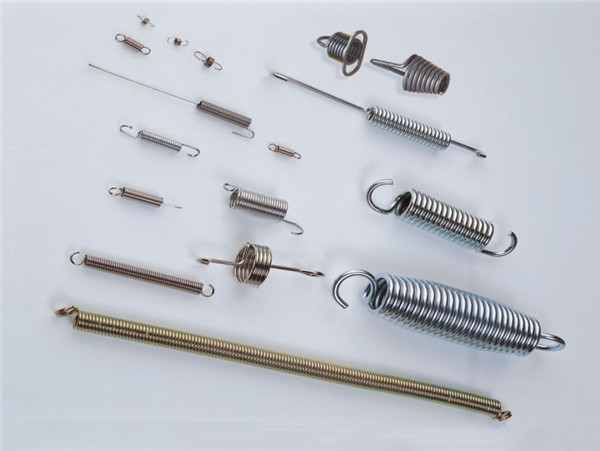

Really want to find myself liking the MIM or spring/shell is very simple, the most important thing is that you have to choose a professional metal products manufacturer, cluster technology limited precision hardware co., LTD. Is a production of various kinds of high precision springs, shrapnel for spindle one-stop hardware products manufacturer, to provide clients with metal plastic forming and spring/shrapnel and other related products.

Post time: Aug-22-2020